Case Studies

Learn more about the product design, rapid prototyping & low volume production work we have done for customers.

-

Everbuild - Seal Rite Tape Dispenser

-

LG Harris - Lock N' Roll

LG Harris - Lock N' Roll -

Pulsar Fusion -

UK's First Green Rocket

-

JigTech Pro

JigTech Pro -

CNI Guard -

Manhole Monitoring System

-

B&Q - Performance Power Tools

B&Q - Performance Power Tools -

CMD - CPU Support

CMD - CPU Support -

INK Aviation -

Compact Check-In Kiosk

-

LG Harris - No Loss 3G

-

LG Harris - Gel Paint Brush

LG Harris - Gel Paint Brush -

LG Harris - T-Class Delta Tools

LG Harris - T-Class Delta Tools -

Irwin - Jack Handsaw

Irwin - Jack Handsaw -

LG Harris - Icon Decorating Tools

LG Harris - Icon Decorating Tools -

Fellowes - Smart Suites

Fellowes - Smart Suites -

Fellowes - Desk Foot Support

Fellowes - Desk Foot Support -

CMD - Office Eco Task Light

CMD - Office Eco Task Light -

CMD - Monitor Arm Mount

CMD - Monitor Arm Mount -

Fellowes - I-Spire Laptop Riser

Fellowes - I-Spire Laptop Riser -

Arquella - Nurse Call System

Arquella - Nurse Call System -

Towndate Property - Reverse

Engineering Light Fixtures

-

Rapid Rhythm -

Handheld ECG Device

-

VIOA - UVC Steriliser

-

Turbo Reverse Engineer

-

Tommee Tippee -

No Knock Cup

-

Fellowes - I-Spire Laptop Riser

Fellowes - I-Spire Laptop Riser -

Shrewsbury Flaxmill Model

Shrewsbury Flaxmill Model -

Arquella - Nurse Call System

Arquella - Nurse Call System -

LG Harris - No Loss 3G

-

KANO Computing -

Wand Prototyping

-

Train Models

-

Tide Spin Brush

-

Rapid Rhythm -

Handheld ECG Device

-

Gumption Squad -

Costume Prop

-

Apawtiser -

Treat Cutter Trays

-

Mobile Power -

Battery Prototyping

-

Pandrol -

Tradeshow Model

-

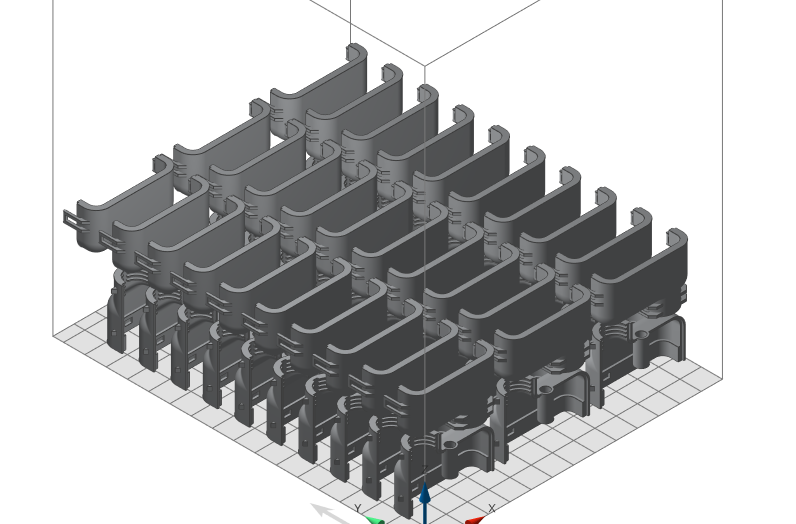

XEROS -

SLS Filters

Get high-quality UK manufactured parts

Supporting businesses to save money and stress with our services for over 20 years.

High quality SLA, SLS & MJF parts guaranteed

1-5 Day lead times

20+ Materials Available

Prototyping, One-Off & Batch Manufacturing Available

ISO 9001:2015 certified

Submit the form > Receive a quote within 24-48 hours > Order & get your parts