MJF 3D Printing

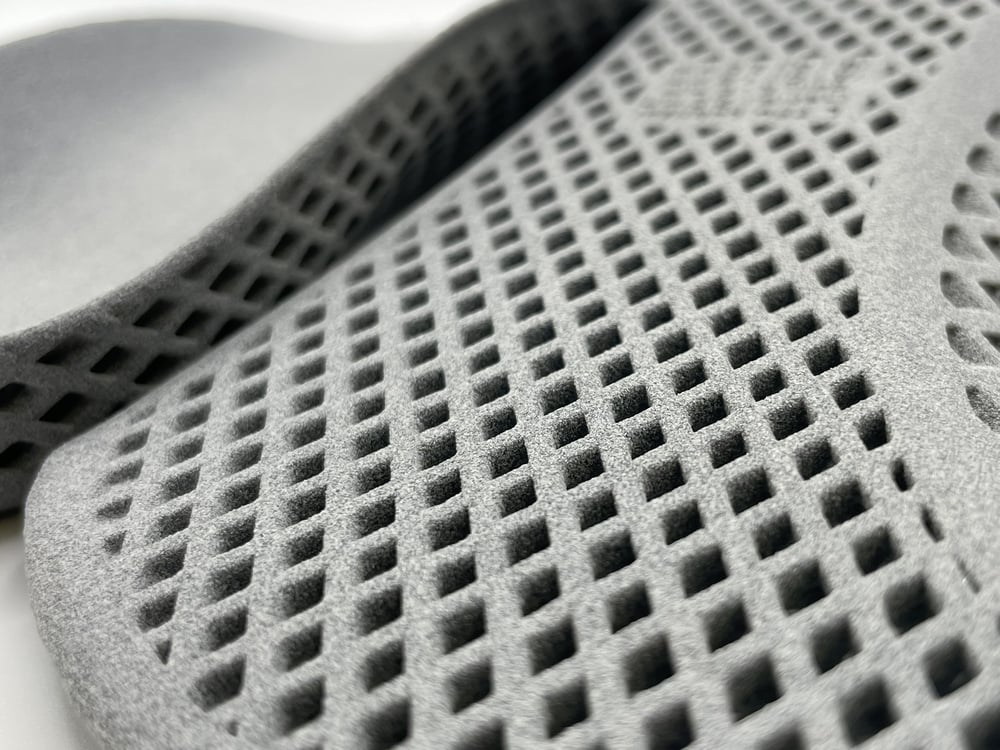

A powder bed fusion 3D printing process that produces strong end-use parts.

Accurate | Easy Repeatability | High-quality

What is MJF 3D Printing?

MJF 3D printing, or Multi Jet Fusion, is an industrial additive manufacturing technology developed by HP that uses a powder bed fusion process to build parts layer by layer. It’s known for producing strong, detailed, and functional plastic parts with excellent speed and surface quality.

The process works by spreading a thin layer of nylon powder across the build platform. Then, an array of inkjet nozzles selectively applies fusing and detailing agents to define the part. A heat source then passes over the layer, causing the treated areas to fuse. This is repeated layer by layer until the object is fully formed.

MJF is commonly used for:

- Automotive and aerospace components.

- Medical devices and custom orthotics.

- Functional prototypes and end-use parts.

- Consumer products and housings.

Key Benefits of MJF 3D Printing

Strong, functional parts.

No support structures needed.

Excellent dimensional accuracy.

Quick turnaround.

Isotropic strength.

Scalable for production.

When should you use MJF 3D printing?

Strong, durable, production-ready parts

Repeatability and accuracy

Scaling from prototype to small batch production

Contact us today to get a quote or discuss your part design. Our team of engineers and technicians are ready to help you get the most out of 3D printing—fast, accurate, and cost-effective.

NDA needed? No problem, download here and email to info@ame-3d.co.uk.

Specifications

| Dimensions | 380 x 284 x 380mm | |||

| Resolution | Layer Thickness: 80 microns | |||

| Min. Wall Thickness | 1mm | Living Hinge 0.5mm | |||

| Tolerances |

PA 12 & 11 - ± 0.3% (min: ± 0.15 mm) TPU 90A - ± 0.9% (XY) up to ± 1.8% (Z) |

|||

Get MJF 3D Printed Parts

Get an instant quote.

Materials

If the material you require isn't listed, please contact our sales team.Finishes

- Vaporfuse surfacing (VFS).

- Poly-shot surfacing (PSS).

- Dyeing black.

Need some more 3D printing help?

Download our guide to getting cost-effective manufacturing & understanding

which process suits your application.

Multi Jet Fusion 3D Printing FAQs

What materials are used in MJF printing?

MJF primarily uses polyamide-based materials such as:

- Nylon PA12 (strong, durable, and versatile)

- Nylon PA11 (more flexible and impact-resistant)

- PA12 Glass Bead (stiffer with enhanced heat resistance)

- TPU (Thermoplastic Polyurethane) (flexible and rubber-like)

See above for a list of MJF 3D printing materials we offer, you can also request them through emailing us at info@ame-3d.co.uk.

What industries use MJF 3D printing?

MJF is widely used in:

- Automotive (functional prototypes, spare parts)

- Aerospace (lightweight, high-strength components)

- Medical (custom prosthetics, orthopedic models)

- Consumer goods (wearable devices, electronics enclosures)

How can I optimise my design for MJF printing?

We have created a design guide with specifications for our 3D printing, vacuum casting and reaction injection moulding technologies.

Alternatively, if you require assistance with CAD design, we have our own design department. Send an email to design@ame-3d.co.uk.

How long does it take to 3D print a part using MJF?

MJF is a fast 3D printing process, typically producing parts within 24 to 48 hours, depending on the part size, complexity, and order volume.

MJF 3D Printing Quote

Supporting businesses with our MJF 3D printing services for over 20 years.

High quality MJF parts guaranteed

1-6 Day lead times

2+ Materials Available

Excellent Customer Service & CAD Advice Provided

ISO 9001:2015 certified

Submit the form > Receive a quote within 24-48 hours > Order & get your parts

Need an NDA? Download it here & send it to info@ame-3d.co.uk.