SLA 3D Printing

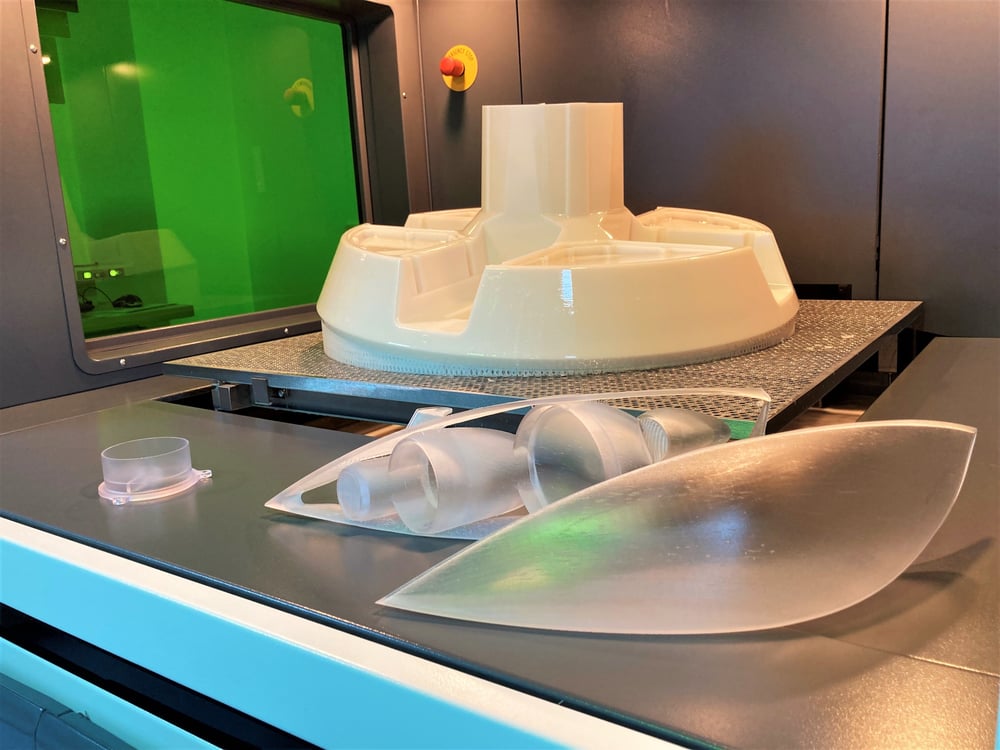

One of the most tried, tested & efficient 3D printing technologies. Stereolithography cures resin layer-by-layer using a laser.

Cost-effective | Lead times from 1 day | High-quality

What is SLA 3D Printing?

SLA 3D printing, Stereolithography, is a type of additive manufacturing technology that uses a laser to cure liquid resin into hardened plastic, layer by layer. It’s one of the earliest 3D printing methods and is known for producing highly detailed and smooth-surfaced parts.

The process works by aiming a UV laser at a vat of photopolymer resin. The laser traces a pattern on the surface of the liquid, solidifying it where it hits. The build platform then moves slightly, and the next layer is traced and cured. This is repeated until the object is fully formed.

SLA is commonly used for:

- Tradeshow models.

- High resolution applications.

- Dental & medical models.

- Prototypes with fine details.

Its main advantages are high precision, smooth surface finish, and the ability to produce complex geometries. A wide selection of materials with different properties are used within resin 3D printing.

.jpg?width=1000&height=750&name=cropped-Image%20(6).jpg)

Key Benefits of SLA 3D Printing

High precision and accuracy.

Smooth surface finish.

Material versatility - including transparent resins.

Fast turnaround.

Achieves complex geometries.

Can build large parts thanks to our large format SLA machine.

When should you use SLA 3D printing?

When high detail and surface finish are critical

When fine details or small features must be reproduced accurately

When early-stage validation is the priority

Contact us today to get a 3D printing quote or discuss your part design. Our team of engineers and technicians are ready to help you get the most out of 3D printing—fast, accurate, and cost-effective.

NDA needed? No problem, download here and email to info@ame-3d.co.uk.

Specifications

| SLA Machines | RS Pro 800 | Pilot 450 | 3500 | Viper |

| Layer Thickness | 0.07-0.25mm | 0.05-0.1mm | 0.1mm | 0.05-1mm |

| XYZ | 800 x 800 x 550mm | 450 x 450 x 400mm | 350 x 350 x 350mm | 250 x 250 x 250mm |

| Materials |

UK1618 Accura PIV |

Accura Xtreme Accura HPC |

Accura Xtreme Accura ClearVue |

Accura Xtreme Accura ClearVue Accura 25 Somos® WaterClear Ultra |

| Tolerances | ± 0.2% (with a lower limit of ± 0.2mm) | |||

| Supported / Unsupported Walls | 1mm - Standard | 0.5mm Hi-Res | |||

| Connections |

0.2mm assembly connections 0.2mm snug fits |

|||

| Engraving | 0.5mm | |||

| Embossed Details | 0.5mm | |||

| Holes (Diameter) | 0.5mm - Standard | 0.3mm - Hi-Res | |||

Get SLA 3D Printed Parts

Get an instant quote.

Materials

If the material you require isn't listed, please contact our sales team.Accura ClearVue

Accura ClearVue

Durable, polypropylene-like material.

Ideal for functional components including automotive styling parts.

UK1618

UK1618

High-strength Nylon ABS-like plastic.

Ideal for low to medium part runs, large automotive rapid prototypes & medical devices.

Accura HPC

Accura HPC

High speed & high rigidity nanocomposite. Ceramic-filled.

Well suited for automotive & aerospace wind tunnel models.

Finishes

Grade 1 (Free)

- Post-curing.

- Supports removed.

Optional: Bead blast.

Note: Scarring from build layers is still visible.

This finishing grade is a standard free finish that comes with all parts.

Grade 2

- Dry and wet sanding to remove build lines.

- Shotblast finish.

Grade 3

- Primer.

- Single paint colour. Gloss, Matte, Satin, Spark finish.

Custom

This level of finishing is a completely custom finish to your project.

Need some more 3D printing help?

Download our guide to getting cost-effective manufacturing & understanding

which process suits your application.

Stereolithography 3D Printing FAQs

How does Stereolithography compare to other 3D printing methods?

SLA 3D printing stands out for its high precision and smooth surface finish, making it ideal for detailed prototypes and aesthetic models. Unlike SLS, which uses powdered materials for durable, functional parts, SLA’s photopolymer resins are less robust but offer excellent detail and clarity. LCD, similar to SLA, is faster but may show more visible layer lines. Overall, SLA excels in applications where fine detail and smooth surfaces are critical.

What materials are used in SLA 3D printing?

Stereolithography uses photopolymer resins which can have properties such as having a high heat resistance, transparent, ceramic-like and more.

See above for a list of SLA 3D printing materials we offer, you can also request them through emailing us at info@ame-3d.co.uk.

What industries benefit most from SLA 3D printing?

Industries like dental, jewelry, medical, and consumer goods benefit greatly from SLA’s precision and aesthetic qualities, often using it for prototyping, modeling, and detailed custom parts.

What is large format SLA 3D printing?

Large-format SLA 3D printing refers to the use of stereolithography (SLA) technology to create oversized, high-resolution parts and prototypes. Traditional SLA 3D printing is often associated with smaller parts due to its reliance on resin tanks and the size of available platforms. However, large-format SLA expands this capability, allowing for the production of objects without the need to be split and rejoined.

Our largest platform size is 800x800x550mm.

How fast is SLA 3D printing?

Turnaround time varies, but small to medium parts can be printed within 24–48 hours, depending on complexity and post-processing needs.

How do I optimise my design for SLA printing?

We have created a design guide with specifications for our 3D printing, vacuum casting and reaction injection moulding technologies.

Alternatively, if you require assistance with CAD design, we have our own design department. Send an email to design@ame-3d.co.uk.

SLA 3D Printing Quote

Supporting businesses with our SLA 3D printing services for over 20 years.

High quality SLA parts guaranteed

1-5 Day lead times

Large build platform size

9+ Materials Available

Excellent Customer Service & CAD Advice Provided

ISO 9001:2015 certified

Submit the form > Receive a quote within 24-48 hours > Order & get your parts

Need an NDA? Download it here & send it to info@ame-3d.co.uk.