Subsea Manufacturing

Delivering robust, high-performance parts for extreme environments — we combine specialist subsea product design and advanced vacuum casting & 3D printing services to support innovation below the surface.

Designing for subsea environments comes with complex engineering challenges — from high-pressure resistance to corrosion, sealing, and performance in low-visibility or high-current conditions. At AME-3D, we work with marine, offshore, and subsea engineering teams to accelerate development through expert subsea product design, vacuum casting, RIM moulding and 3D printing.

Our capabilities support everything from functional prototypes to low-volume components — helping businesses validate concepts, reduce risk, and move efficiently from design to deployment. Whether you’re developing ROV housings, sensor brackets, or cable management systems, we deliver solutions built for the depths.

Quick Turnaround Times

Highly

Quality

In-House Design Team

Custom Finishes Available

Variety Of Material Selection

Prototypes, Development & End-Use Parts

End To End Development

UK-based ISO 9001:2015 Certified

Download an NDA here, and email it to info@ame-3d.co.uk if required before uploading parts or discussing project specifications.

Sensor & Instrument Housings

Subsea sensors and data-gathering instruments require durable, watertight enclosures. We design and produce housings that protect sensitive electronics from pressure, impact, and saltwater corrosion.

Using subsea 3D printing, we deliver fast-turnaround prototypes and short-run production parts with high precision — ideal for testing fit, integration, and deployment before committing to final materials.

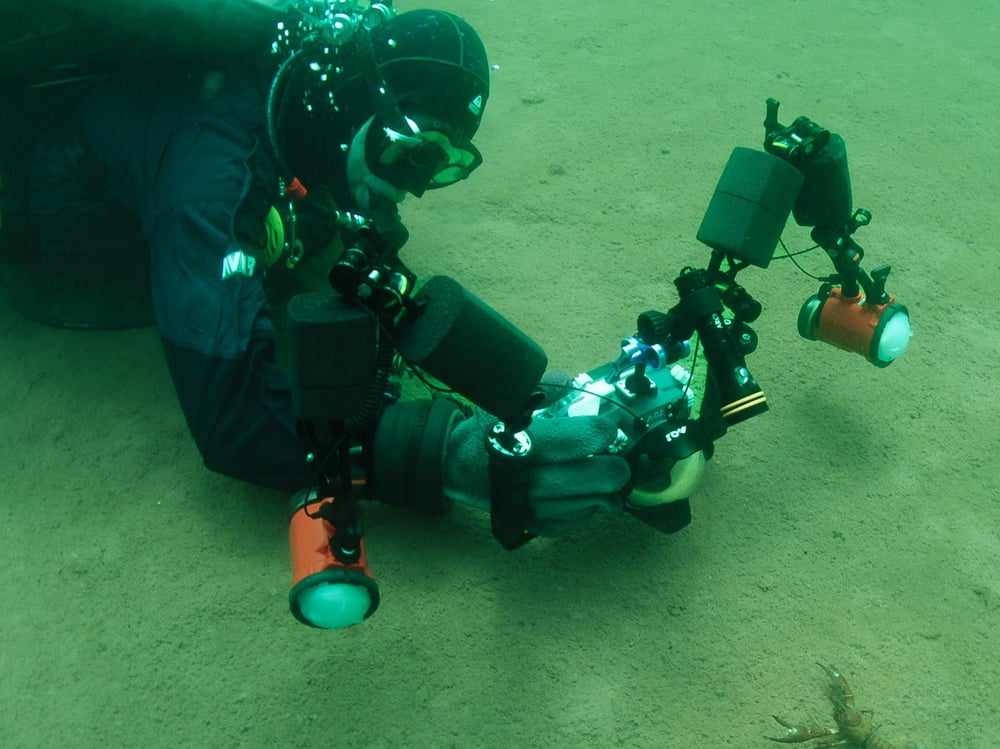

ROV & AUV Components

Remotely operated and autonomous vehicles are at the heart of subsea operations. We support the development of functional parts such as propeller guards, housings, camera mounts, and internal brackets.

Our subsea product design expertise ensures every part is engineered with hydrodynamics, durability, and access in mind. With 3D printing & vacuum casting, we help you iterate faster and validate form, fit, and flow before fabrication.

Buoyancy and Hydrodynamic Aids

Subsea systems often require neutral or positive buoyancy, and finely tuned hydrodynamic elements. We support the design of custom floats, flow directors, and fairings that enhance performance and reduce drag.

With rapid subsea manufacturing technologies, we can deliver lightweight, form-specific parts for testing and low-volume use — helping teams trial, improve, and scale effective solutions faster.

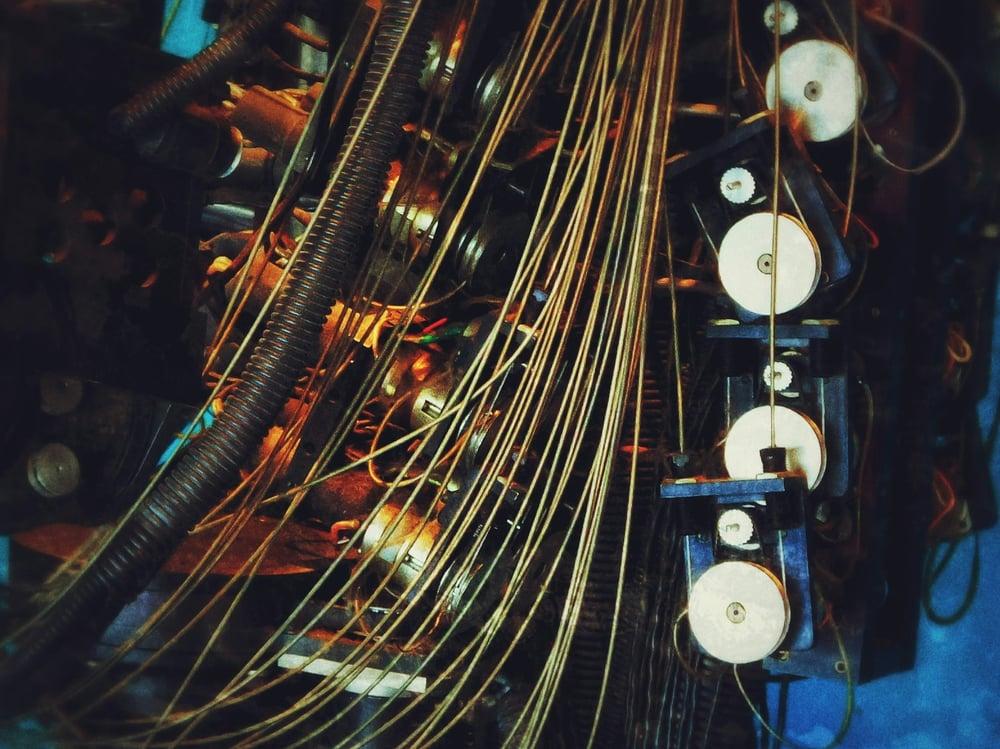

Cable Routing & Protection Systems

Effective cable management is critical in underwater systems, where movement, abrasion, and pressure can affect signal and power integrity. We design custom clamps, channels, and sealing features to protect and secure subsea cabling.

We provide flexible, on-demand solutions that fit your assembly precisely — reducing reliance on off-the-shelf components and increasing long-term reliability.

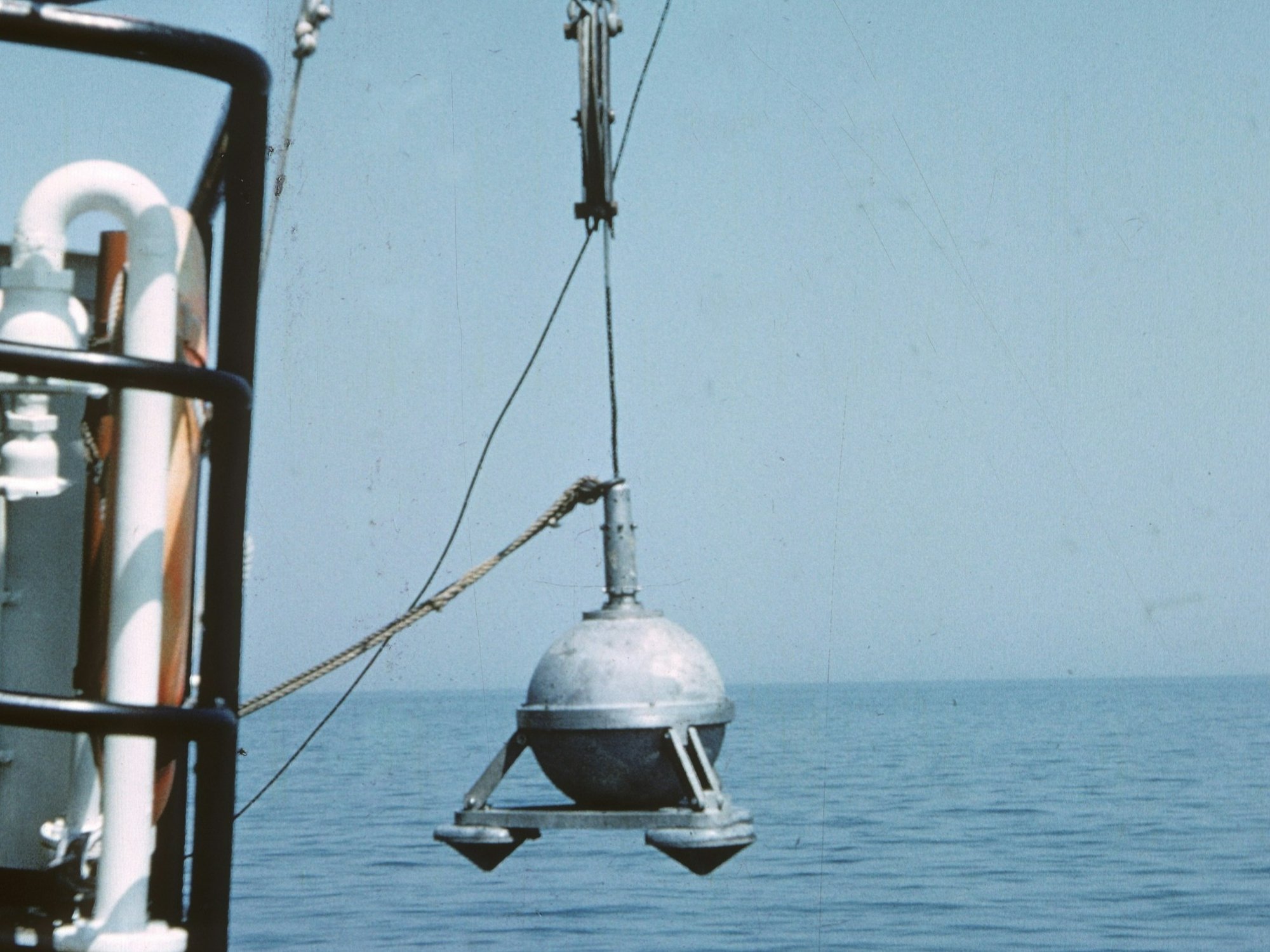

Deployment and Handling Equipment

We help design and prototype auxiliary gear used to transport, deploy, or retrieve subsea assets — including lifting lugs, protective casings, and rigging accessories tailored to your equipment.

By combining subsea product design with agile 3D printing, we help you create purpose-built, application-specific tools that streamline operations and withstand offshore handling environments.

Get In Touch With Our Subsea Experts

Got a STL/STEP File?

Submit it here for a quote.

Where to find us

+44 (0)1909 550 999

Momentum House, Church Lane, Sheffield, S25 2RG

Monday - Friday | 9AM - 5PM