Choosing the right prototyping partner can make or break your product development timeline. The wrong choice could mean missed deadlines, poor-quality parts, or spiralling costs. The right choice? Faster time to market, reduced risk, and a partner who can support you from first sketch to final production.

Before you commit, ask these five essential questions.

1. Do They Have the Right Technologies for My Project?

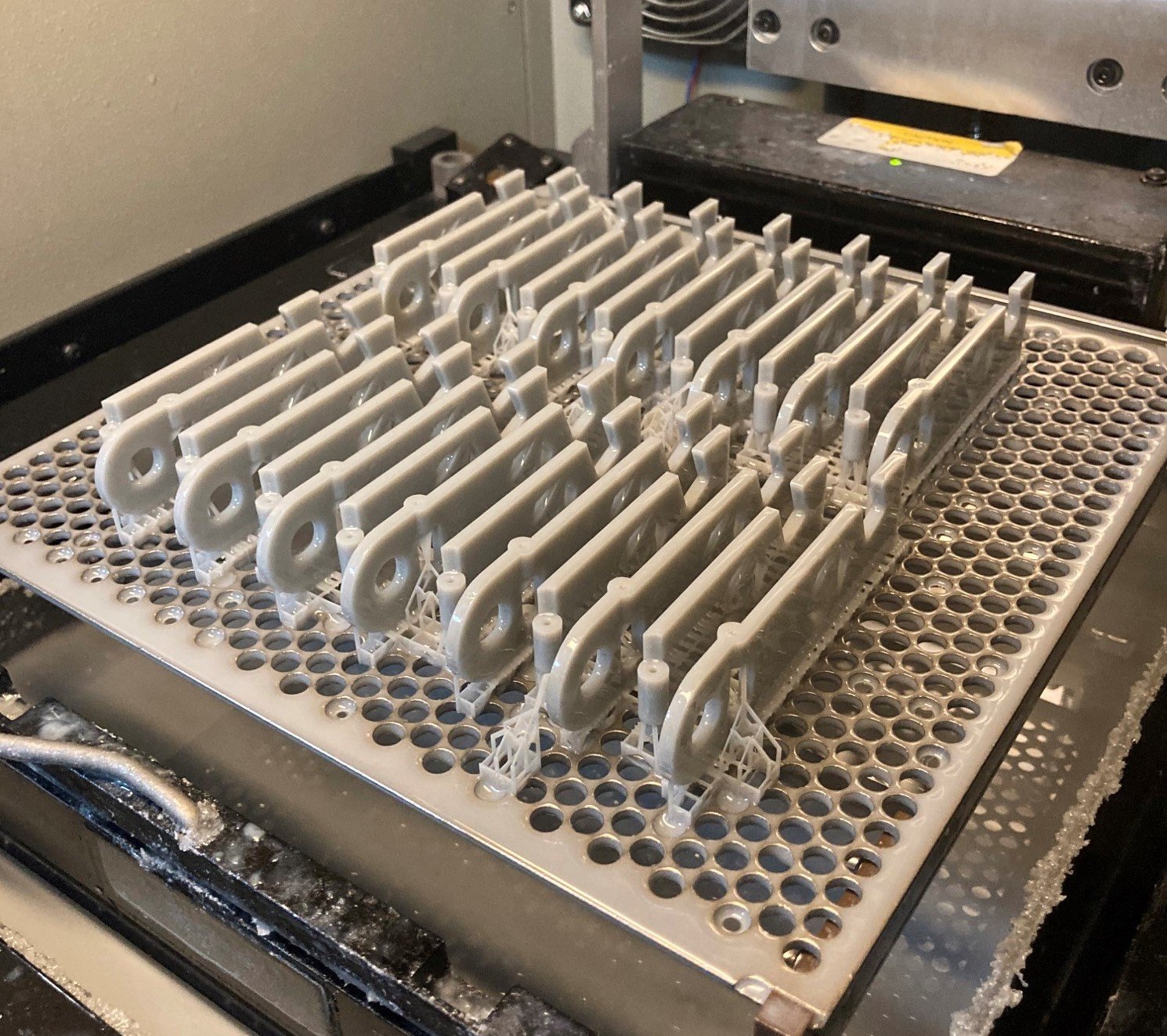

Different prototypes demand different manufacturing methods — SLS 3D printing for complex geometries, vacuum casting for low-volume runs, CNC machining for high-precision parts.

Make sure your partner offers a range of technologies so you’re not forced into one process that might not be the best fit.

2. Can They Advise on Design for Manufacture?

A good prototyping partner won’t just make your parts — they’ll improve them. Ask if they can review your CAD files and suggest design tweaks to save cost, improve function, or reduce lead times. A good partner will more than likely have their own in-house design team who can assist further. This expertise is invaluable in avoiding expensive mistakes.

3. How Fast Can They Turn Parts Around?

Speed is often critical in product development. Check if your partner offers rapid turnaround services and ask for realistic lead times based on your specific project — not just a generic promise.

4. Do They Understand My Industry’s Standards?

Whether you’re in automotive, aerospace, consumer products, or medical devices, industry-specific requirements matter. Look for partners with experience in your sector and the ability to meet relevant compliance and quality standards.

5. What Happens After the Prototype?

Some partners can only deliver prototypes, while others can bridge into low-volume or full-scale production. Choosing a partner who can scale with you means less time wasted onboarding a new supplier when you’re ready to move forward.

Why These Questions Matter

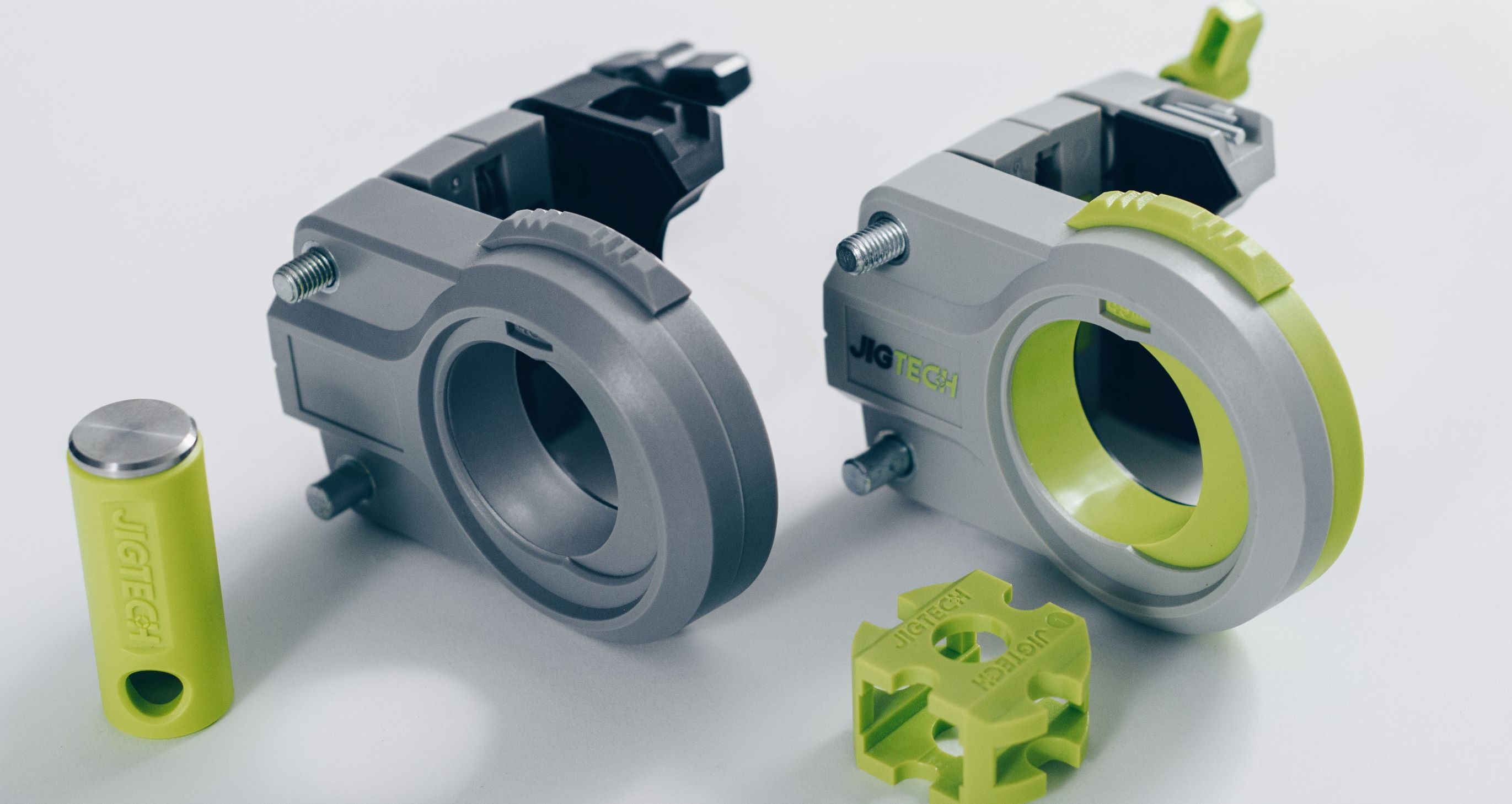

Prototyping is more than just making “something you can hold.” It’s a critical stage where design, function, and manufacturability come together. The right partner will save you time, money, and headaches — while giving you the confidence to move into production.

At AME-3D, we combine a broad range of technologies with design expertise, rapid lead times, and production scaling — making us a trusted partner for UK manufacturers, engineers, and product designers.

Contact us to discuss your next prototyping project.