How you orient your parts plays an important role in the final quality of your 3D-printed parts. Whether you are 3D printing for an end-use part or a prototype, your orientation matters to achieve your desired properties.

There are a few things to consider between different 3D printing technologies including SLS & SLA as one is a resin-based technique and the other uses powder.

What does orientation affect?

When you 3D print, regardless of which technology you use, it can affect several different properties and change the outcome of your part.

Properties that can be affected by orientation include:

- Strength

- Warping

- Finishes

- Print Times

- Costs

- Accuracy

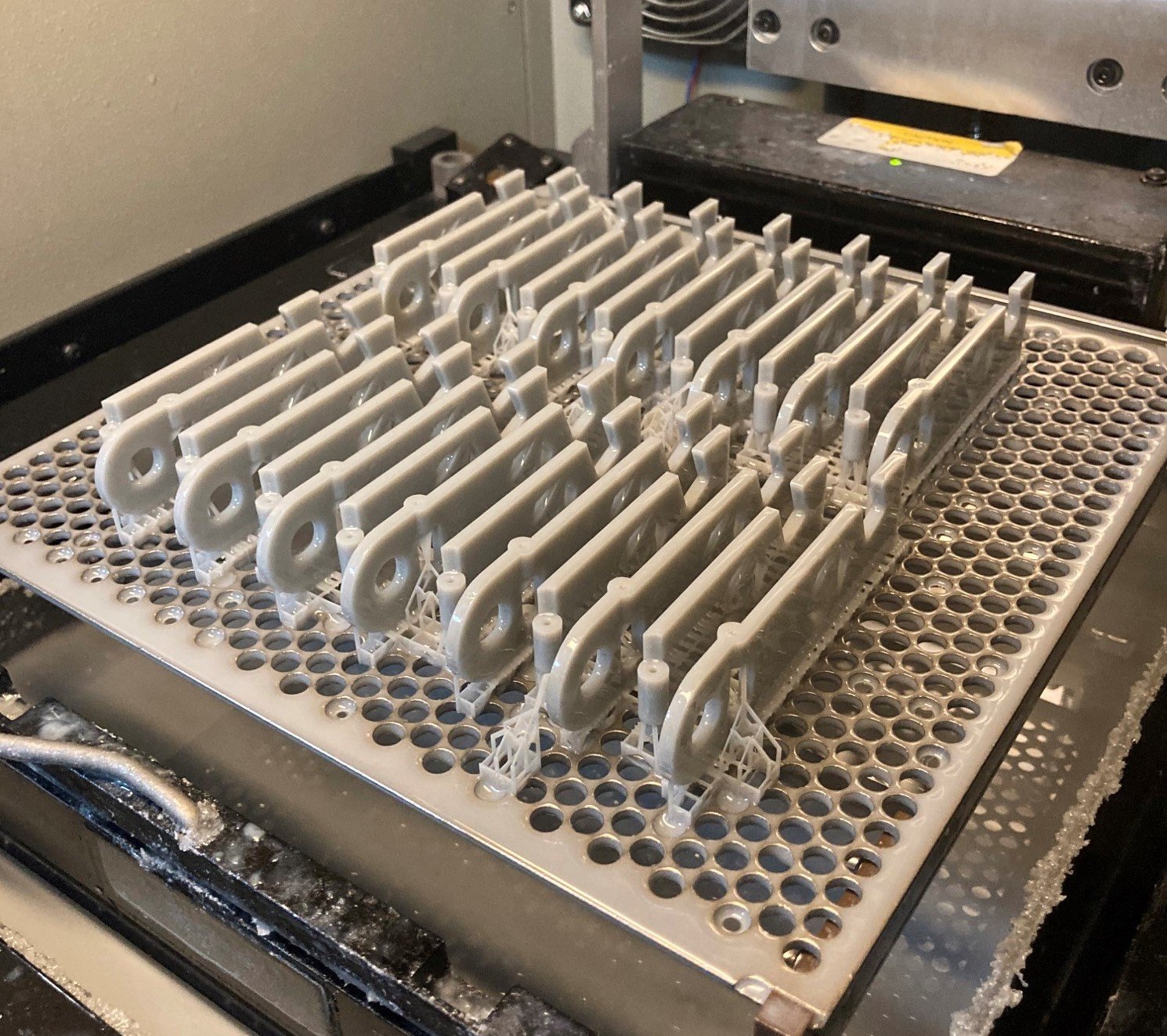

Does Part Orientation Affect SLA 3D Printing?

If you were to SLA 3D print an item, deciding whether to print it vertically or horizontally depends on the characteristics you need from the part. You need to be mindful of the support structures required either way you print it and whether the lead time is an important factor in this.

Support structures also mean an additional cost. If your part is complex and orientated in a way that has sections sticking out, SLA machines will need to build additional structures to supplement this leading to additional costs.

Best practices for orienting SLA builds include:

- Placing the build at an angle where there are no overhangs.

- Orient large flat surfaces at a slight angle to increase the success rate.

- Rotate important features of a 3D print away from the build plate/support structures so that build lines are easily hidden in post-processing.

SLA 3D printed parts are isotropic, meaning the properties will be the same in whatever direction they’re measured in. Therefore, orientation doesn’t affect the strength and integrity of SLA-printed parts as much.

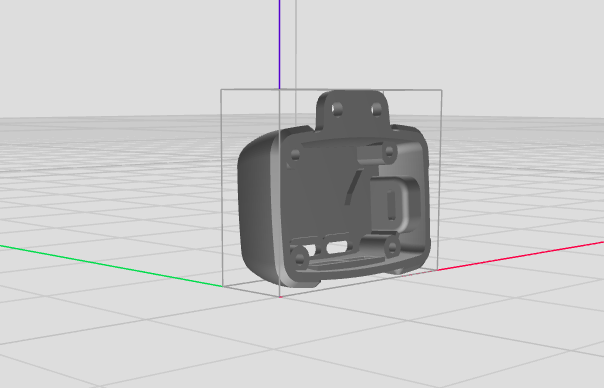

Does Part Orientation Affect SLS 3D Printing?

As SLS 3D Printing doesn’t require supports, does the orientation matter? Although SLS 3D printing is powder based, the orientation still matters as it can affect several different properties of a part.

The first thing to consider with orientation in SLS 3D printing is the finish quality. Generally, the lower area of a part will usually have a grainy finish in comparison to higher up in the part so it is important to factor this in when angling your part.

Sometimes warping of a flat part in SLS is inevitable due to extremely high temperatures. Orientation can help to reduce the chances of this happening by rotating the part on all axis.

SLS 3D Printing melts & solidifies plastics which means that parts are stronger in the X & Y axes in comparison to the Z axis. If strength is a major factor in part requirements, it is best to ensure that load paths are not on the Z-axis.

Summary

Overall, the orientation of 3D printing parts does matter and can matter a lot in both SLS & SLA. Our 3D printing experts can advise you on the best orientation for your parts depending on the specifications of your project unless you advise otherwise within your CAD submission notes.

With over 20 years of experience in 3D printing using different technologies, we are the UK’s leading 3D printing service based in Sheffield. We offer a variety of finishing options and have the knowledge to push your project forward. If you already have your CAD file ready to 3D print, simply submit it here and our sales team will be in touch with a quote shortly.

CAD not quite prepared or want to discuss our services? Feel free to get in touch via email or phone below.

Phone: 01909 550999