Magtec design, develop, manufacture & install EV drive system for HGV commercial, passenger, defence and special vehicles.

“We’ve found that AME-3D’s technologies work perfectly in our application. Our vehicles are not being mass produced yet, and as such, a lot of our components are only required in low to medium volume. Using the SLS nylon means that we can produce parts that are tough and robust, very repeatable, and it keeps the design flexible. We could move to injection moulding but the cost of the tool would make it financially unviable at these volumes and we would have to fix the design. AME-3D’s ability to produce the parts we need and deliver them quickly means that we don’t need to hold stock, tying up cash and space in our facility. We can operate in a lean way because we can rely on the delivery and quality.”

- Jim Erskine, Head of Commercial, Magtec

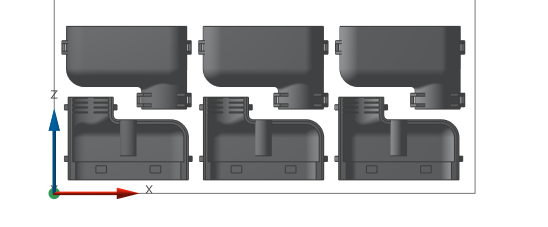

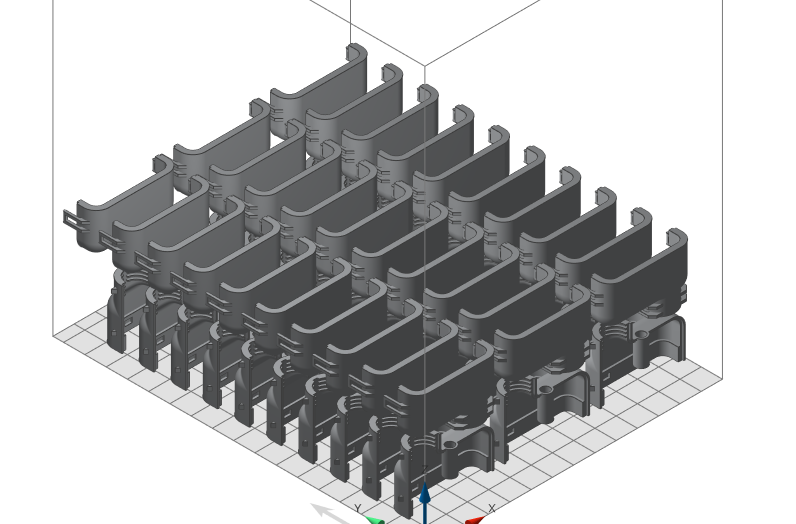

SLS 3D Printing Using Nylon

Our selective laser sintering capability for 3D printing uses Nylon material which cost-effectively produces industrial strength parts when needed at low to medium volume.

We can provide a 2-4 day turn around for SLS components, with guaranteed high-quality first time, every time. Submit your CAD files here.