Recently we were approached by Moto-Mate.com, a motorbike accessories provider. The Managing Director, Phil, had a design in mind for a bespoke light holder for a KTM bike.

A Project For Low Volume Manufacturing

Phil shared his designs with our qualified manufacturing team along with his target price and volume of parts. We assessed the project and came back with several options for him. These included direct manufacture options with SLS or MJF, or the more tried and tested vacuum casting process.

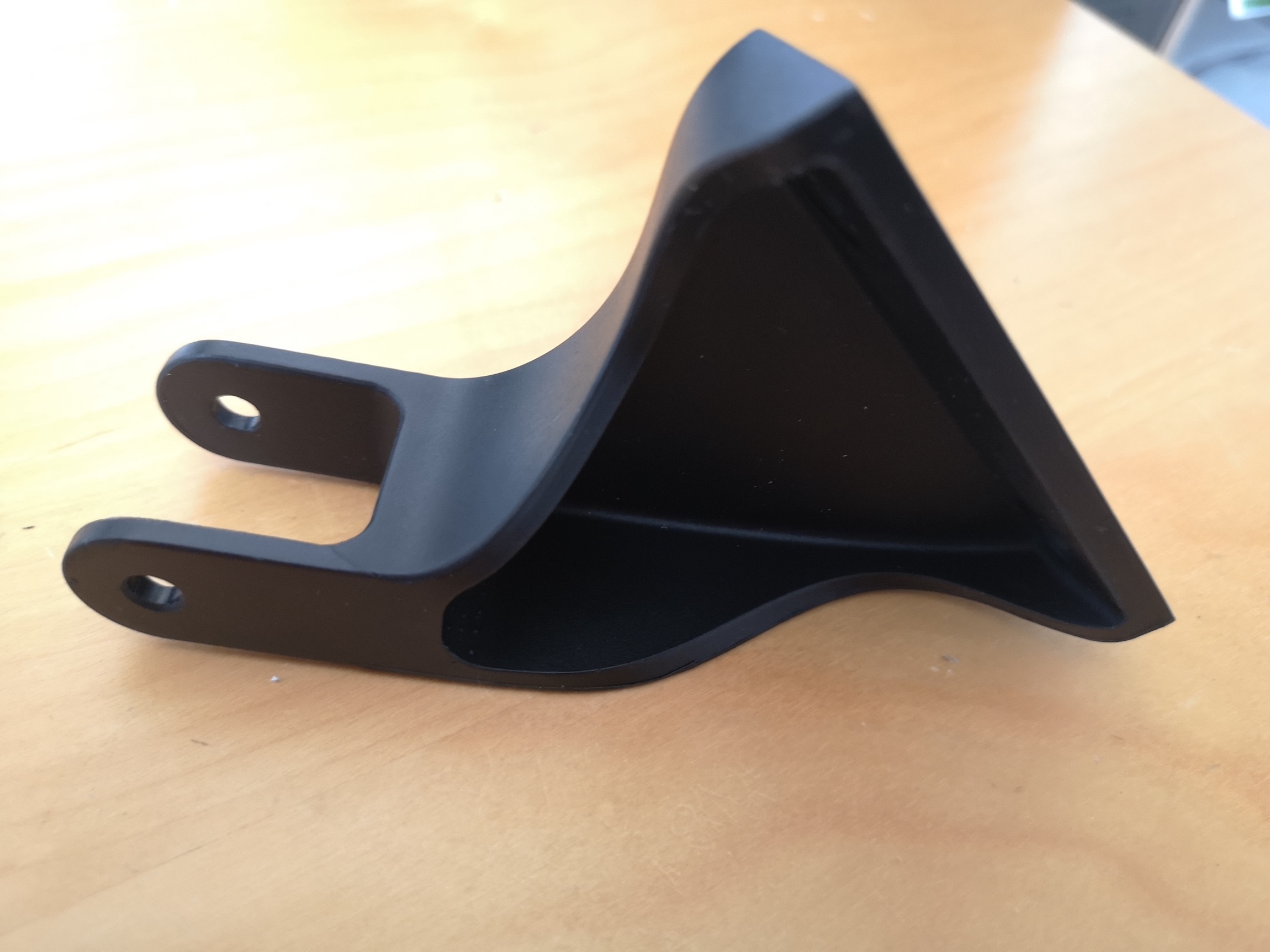

Phil opted, on this occasion, to go down the vacuum casting route. He wanted to be able to offer his customers a really neat, well-finished, matt black, robust light mount. This is something our 3D manufacturing workforce was more than capable of achieving.

Vacuum Casting For Motorbike Accessories

We generated the SLA from Phil’s CAD model, discussed how we would make the tool with him to ensure the best possible finish and as soon as we had 1st off parts from the tool, we sent them to him to inspect.

Once they were approved, we proceeded with the production run of 40 sets, and they were delivered within 3 weeks of starting the project at the price Phil needed them. This was a direct manufacture, vacuum casting project that was delivered within budget, on time & exceeded expectations.

Considering Alternate 3D Manufacturing Options

We could have gone to injection moulding but there likely isn’t the market for 10,000s of these parts out there and the tooling price alone would have exceeded the whole project cost.

We take real pride in helping our customers to achieve their goals within their price/speed/quality parameters. This was Phil’s first contact with AME-3D and it’s not been his last. We have already moved on to direct manufacturing of his latest parts using MJF.

An Impressive Manufacturing Project

Phil was extremely pleased with the 3D print manufacturing services that we delivered and had this to feedback...

“As a small reseller of motorcycle accessories, Moto-Mate value service and product quality as the two most important criteria in surviving in an extremely competitive market.

We have had more than our fair share of failed delivery and product quality that just doesn’t meet our requirements.

In the quest for yet another supplier, Google returned a result for AME-3D so an enquiry was sent.

Within 24 hours, Rich offered me 3 different solutions with an overview of each, a brief phone conversation followed and a costed proposal was sent over. Due to my previous experience with false promises I asked for a pair of samples before committing to the first production batch. These were turned around really quickly and on receipt, they looked beautifully finished and fitted perfectly.

I am now in possession of the production batch, delivered earlier than advised and the quality is as per the samples.

I am now working on two more products as I have finally found the quality of partner that I have been searching for.

Thanks Guys”

Use Low Volume Manufacturing For Your Next Project

Using our direct manufacturing services means we are able to bridge the gap between prototypes and full-scale production.

Direct manufacturing can help identify hidden issues before mass production begins, reduce tooling costs & allow faster design changes among many other great benefits. Learn more about our low volume production services, here.

If you have a project that needs to be manufactured in a low volume, fill out one of our contact forms, or call us today on +44 (0) 1909 550 999.