April marks the new financial year for a lot of companies. With new budgets becoming available in a challenging financial outlook, it might be time to look into optimising and evolving your current product offerings over the design and introduction of new products. Reverse engineering, done correctly, can increase revenue and increase product life by re-inventing an already popular product to become even more attractive to the consumer.

In this article, we’ll address what reverse engineering is and some of its benefits over starting from scratch with your newly available budgets.

What is reverse engineering?

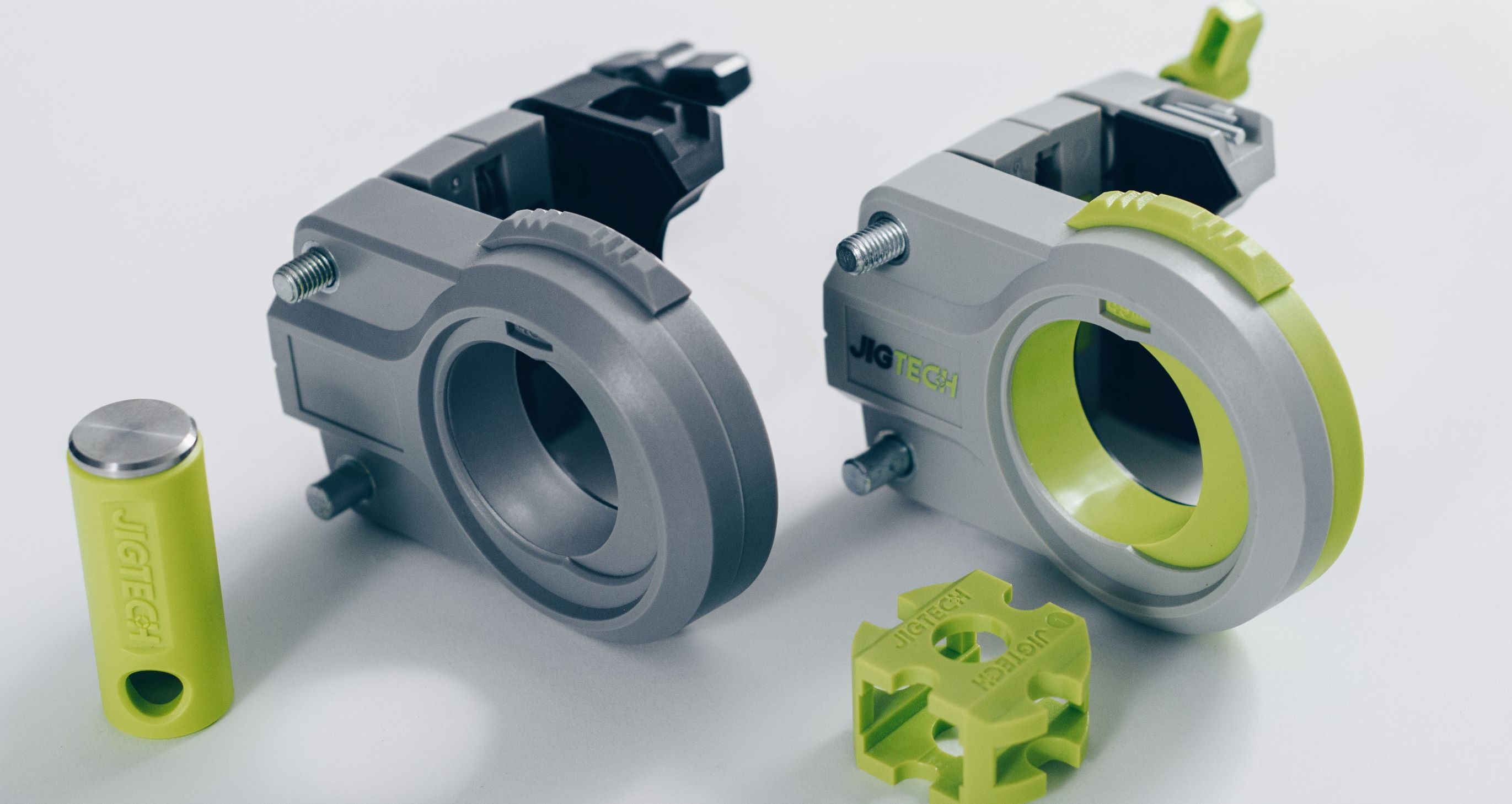

Reverse engineering is the process of taking an existing product that is already on the market and tweaking it in various ways to optimise it. This could be for production efficiency, aesthetics, or user experience. Not only is re-engineering a way to optimise a product, but it’s a way to update in line with new user experiences, evolving sustainability trends and stakeholders' expectations. Re-inventing existing products can be done by:

- Tweaking the design

- Changing the manufacturing method

- Using different materials

- Improving the functionality of the parts

Where do I start?

Re-engineering a product requires a lot of research before any approved changes can take effect. You need to gather all the data you have on your existing product. This data will allow you to evaluate the effectiveness of the product to start with, and then analyse how this can be improved.

A great way to gain additional feedback is through customer surveys, speaking directly to the consumer and end-users.

If you already have a team of designers, it might be useful to engage with an external design consultancy whose speciality includes re-engineering. They are experts at product optimisation, evaluating data and producing recommendations that are driven by their research. They also bring a breadth of design exposure that you don't get when you are focused on the work within a single industry.

What’s the best approach to reverse engineering?

Our design department have an excellent approach to their product design & development work. This approach can be applied to re-engineering as well as new development.

Insight

We explore and outline product opportunities by gathering information about market requirements and by identifying emerging trends.

Fundamentally, responding to user needs, this process enables strategic, evidence-based decisions to be made, and results in richer outcomes.

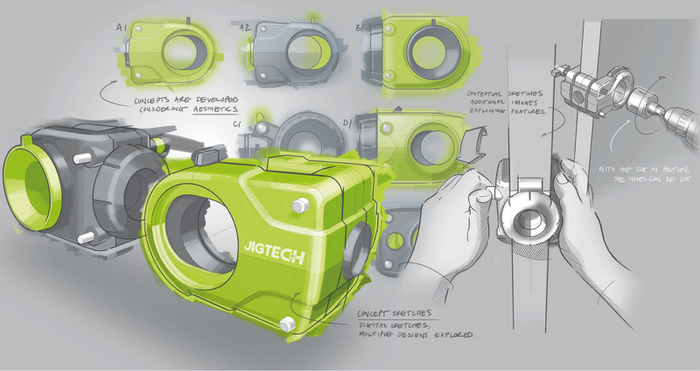

Create

Inspired by the findings from the Insight phase, they generate a range of concepts. By harnessing the opinions of stakeholders and consumers, we methodically narrows the scope of ideas into a single, viable solution.

Validate

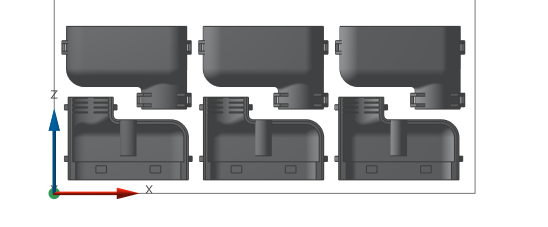

Engineering, prototyping and testing your product solution, we mitigate risk and ensure viability for volume production. Working with us, we can facilitate the manufacturing of the re-engineered product as a prototype and right through to the final version.

Summary

How old are your products on the market? Do you think it’s time to re-engineer in line with the latest trends, saving budget and time?

The benefits of re-engineering include:

- Saves costs

- Already have insights into product performance

- Can become more sustainable through alternative manufacturing and materials

- Save time

- Avoid the market share decline of a product through evolution

If you need help re-engineering an existing product, through our design department, we can offer a full 360-degree approach. Get in touch today.