Most design guides assume high-volume, mass manufacturing. But when you only need 10–200 parts, your design approach should shift dramatically.

Low-volume production — for testing, pilot runs, niche products, early market entry, or bridge manufacturing — requires different decisions around materials, tooling, cost, finish, and production methods.

This is where designers can gain massive advantages by optimising early for low-volume.

1. Batch Size Changes Everything

Why 10–200 parts is a unique window

-

Too small for injection moulding to be economical.

-

Too large for inefficient, slow prototyping methods.

-

Exactly the sweet spot for additive manufacturing, vacuum casting, and hybrid workflows.

Design implications

-

You can prioritise faster iteration over complex tooling.

-

Part designs can afford to be updated between batches.

-

You can avoid mould splits, draft angles, ejector marks and other constraints of mass production.

-

Tolerances, geometry, and features can be far more flexible.

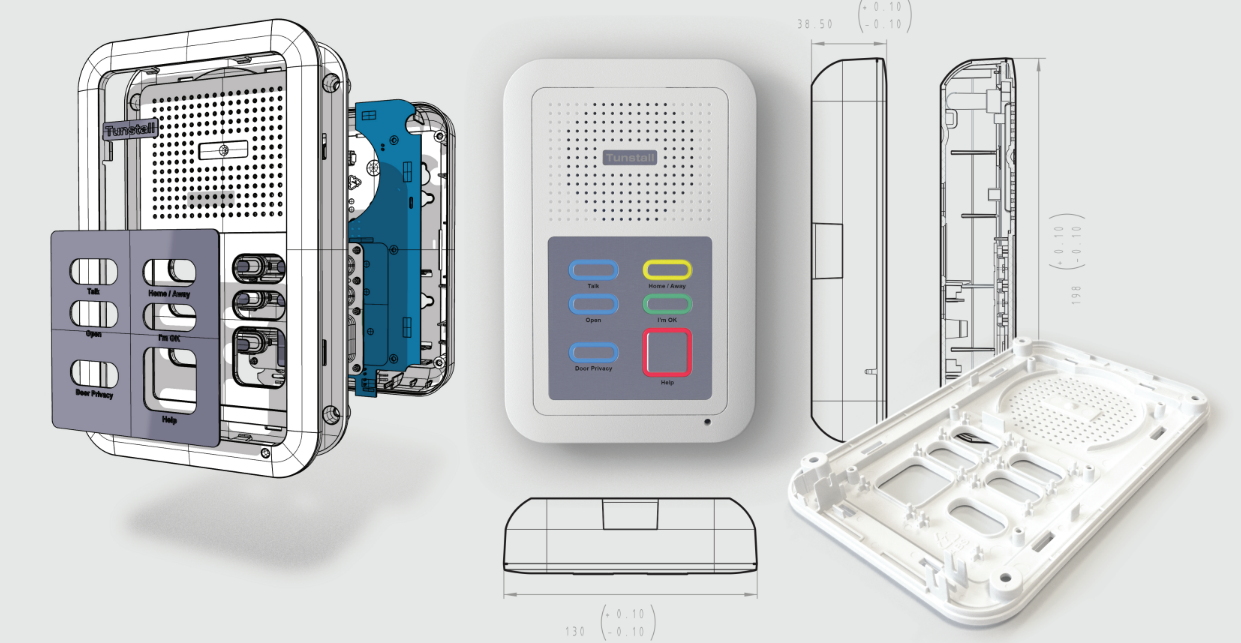

2. Tooling Requirements Are Very Different

No need for expensive hard tooling

For low-volume, you can often avoid:

-

Steel moulds

-

Injection tooling

-

Multi-cavity moulds

-

Long lead times

What you need

-

3D printed masters for vacuum casting

-

Soft tooling (silicone moulds)

-

Modular jigs and fixtures made via AM

-

Design considerations for castability or printability

Design Takeaway

Your design becomes tooling-light, which:

-

Reduces upfront cost

-

Speeds up time-to-market

-

Gives freedom to experiment

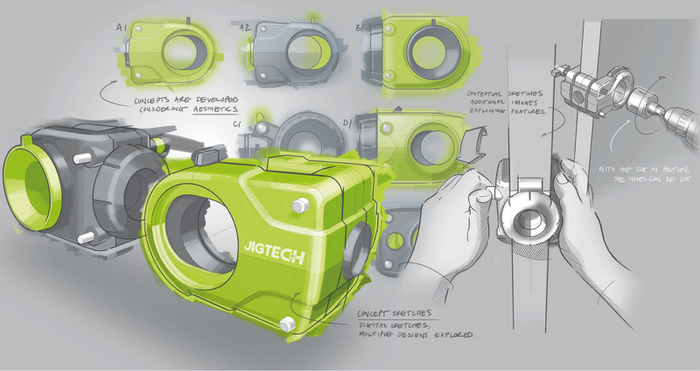

3. Modular Design Becomes Your Best Friend

Low-volume manufacturing is ideal for modular products.

Why modularity wins here:

-

Reduces cost by reusing standard components

-

Allows easier updates to individual sections

-

Helps separate cosmetic from structural elements

-

Enables multi-process workflows:

-

Printed core + cast outer shell

-

Machined bracket + printed housing

-

Design strategies:

-

Break parts into assemblies that suit different manufacturing methods

-

Use standard fixings to avoid custom tooling

-

Allow outer components to change without affecting internal structure

4. Materials Choices Are Broader Than You Think

In low-volume, you’re not restricted by:

-

Resin availability for injection moulding

-

High MOQs

-

Standardised moulding grades

Instead, you can choose materials based on:

-

Performance

-

Aesthetics

-

Cost

-

Speed

-

Post-processing compatibility

Examples

-

SLS / MJF nylon for durable end-use parts

-

SLA for cosmetic housings

-

Vacuum casting resins designed to mimic:

-

ABS

-

PC

-

PP

-

Elastomers (Shore A)

-

Key Design Considerations

-

Wall thickness variation is more forgiving

-

You can choose materials for prototype → production consistency

-

Colour matching and textures become post-processing decisions

rather than moulding constraints

5. Scaling: Small Batches Are Easy to Repeat, Not Always Easy to Scale

When designing for 10–200 units, always consider:

Can this process scale to 500+ if needed?

-

SLS/MJF scales well in batches

-

Vacuum casting scales until mould life ends (20–25 pulls per mould)

-

Machining scales with fixture optimisation

-

SLA scales for cosmetic components but not high-wear parts

Design for scalable workflow:

-

Shared geometries across parts

-

Reduced complex internal features

-

Designing “future moulding ready” versions for later mass-production

-

Keeping options open to transition to injection moulding

6. Cost vs Speed: The Balancing Act

Design choices affect cost instantly

For low-volume manufacturing:

-

Fewer parts = lower assembly time

-

Simple geometries = faster prints

-

Avoiding over-engineering = less post-processing

-

Split large designs into efficient printable sections

Prioritising speed

-

Think “what gets us to test or market fastest?”

-

Use AM for detailed features

-

Use casting for repeatability & finish

-

Design with minimal supports & less finishing work

Prioritising cost

-

Consolidate assemblies

-

Use standard components

-

Remove expensive-to-finish surfaces

-

Choose materials with good print efficiency

7. When to Use AME-3D for Low-Volume Production

Ideal when you need:

-

Repeatable batches

-

Cosmetic-quality finishes

-

Strong, proof-of-concept housings

-

Elastomer or ABS-like cast components

-

Rapid design iteration + full production

Your competitive advantage

AME-3D can support the entire journey:

-

Concept → CAD

-

Design for low-volume

-

Functional prototypes

-

End-use parts

-

Finishing

-

Short-run production with multiple processes in-house

Conclusion

Designing for low-volume production isn’t a cut-down version of designing for mass production — it’s a different discipline altogether.

When designers embrace the flexibility of AM and vacuum casting, they unlock:

-

Faster development

-

Lower costs

-

Better design freedom

-

A product that can get to market (or testing) far sooner

AME-3D sits right at the heart of that opportunity. Need help starting your project? Contact us today.