When people think of additive manufacturing, they often picture rapid prototypes or show-piece models. But one of the most valuable — and most overlooked — uses of 3D printing is in the creation of test rigs, jigs and fixtures.

For engineers and product development teams who need reliable, repeatable and cost-effective tooling, additive manufacturing offers a powerful advantage. At AME-3D, we see more and more customers turning to AM not for their parts, but for the tools they use to test, assemble or validate those parts.

Here’s why.

Why Jigs and Fixtures Are Perfect for Additive Manufacturing

Jigs, fixtures and bespoke test rigs are almost always produced in low volumes. They’re typically one-offs, or small batches created when a new component needs to be tested or assembled. That makes them an ideal fit for additive manufacturing.

1. No tooling required

Traditional machined fixtures often require time-consuming programming, custom setups or even dedicated tooling. With AM, you can go straight from CAD to print — giving engineers a tool in hours or days, not weeks.

2. Complex geometry comes at no cost

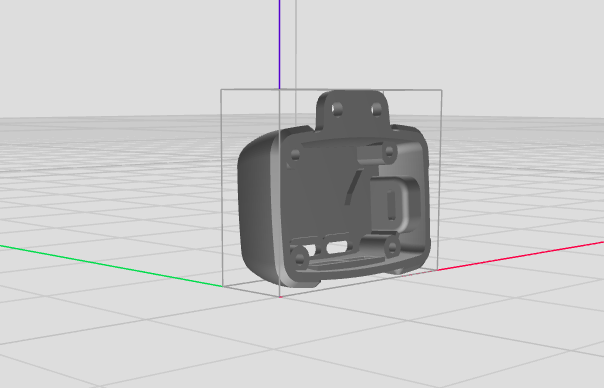

Fixtures often need to cradle parts, align odd shapes, or incorporate internal channels and locating features. AM allows complete design freedom: ergonomic shapes, undercuts, integrated clamps, or textured grip surfaces all become possible without increasing cost.

3. Perfect customisation

Because rigs and fixtures are built around a specific component, custom fit is everything. 3D printing allows you to create housings, nests and alignment features shaped to the exact geometry of the end-use part.

4. Rapid design iterations

As product designs evolve, fixtures need to evolve too. With AM, you can quickly update your CAD, reprint and repeat — supporting fast-paced development cycles without slowing teams down.

How Designing for AM Changes the Way You Create Fixtures

Designing jigs and fixtures using additive manufacturing unlocks possibilities that simply aren’t practical with traditional machining.

Rethinking geometry

AM removes constraints like tool access, draft angles, fixed radii or multi-part assemblies. This means designers can create tools that perfectly suit their purpose rather than compromising to suit a machine or cutting tool.

Embedding functionality into the tool

Designs can include:

-

Internal cable channels

-

Integrated clamps or fasteners

-

Lightweight lattice structures

-

Textured or soft-touch surfaces

-

Identification labels or QR codes

-

Built-in datum points or stops

These features improve ease of use while reducing assembly and material costs.

Improving ergonomics

Fixtures can be designed around human interaction: shaped handles, reduced weight, better balance and improved usability. This is especially valuable for repetitive manufacturing tasks or operators working with delicate components.

Material Choices Make a Big Difference

The choice of material influences durability, accuracy and how the fixture will be used. At AME-3D, we select materials based on performance, handling and the required lifespan.

SLS Nylon (PA12)

-

Strong and lightweight

-

Excellent dimensional stability

-

Suitable for industrial environments and repeat use

SLA Resins

-

High precision

-

Ideal for tight tolerances or fine-feature rigs

-

Great for electronics or component test nests

Vacuum Casting Resins

-

ABS-like and PC-like materials available

-

Rubber-like options for soft-touch grips, overmoulding available

-

Ideal for producing multiple identical fixtures

Hybrid tools

We often combine processes:

-

Machined metal inserts for wear points

-

3D printed bodies for geometry

-

Cast grips or housings for comfort

This gives customers the right balance of strength, accuracy and ergonomics.

Real Benefits for Engineering and Production Teams

Designing test rigs, jigs and fixtures via additive manufacturing gives teams tangible, measurable advantages:

1. Repeatability and accuracy

Fixtures ensure test conditions are consistent. Custom AM fixtures are shaped exactly to the part, improving data quality and reducing human error.

2. Faster assembly and inspection

A well-designed fixture can reduce assembly steps, improve alignment, and make inspection standards clearer.

3. Lower cost per tool

One-off machined fixtures can be costly. AM drastically reduces price without compromising quality.

4. Speed to test

When deadlines are tight, 3D printing enables same-week — tooling production.

5. Better outcomes for iterative design

Every time your part changes, your fixture can change with it. AM gives you flexibility conventional methods struggle to match.

Where AM-Based Fixtures Make the Biggest Impact

We see the greatest benefits in industries with fast-paced development and high precision requirements:

-

Automotive assemblies

-

Electronics & PCB testing

-

Industrial machinery

-

Consumer product testing

-

Aerospace development

-

Medical device prototypes

-

R&D labs

-

Quality assurance teams

Whether it’s a go/no-go gauge, alignment jig, or a complex functional test rig, AME-3D supports the full development cycle.

Why Partner with AME-3D?

At AME-3D, we don’t just print a fixture — we help design it to work better.

Our team blends:

-

CAD expertise

-

Additive manufacturing knowledge

-

Vacuum casting and finishing capability

-

Engineering insight

This allows us to take a concept or requirement and turn it into a functional, ergonomic, and reliable tool that supports testing, assembly or QA.

By keeping design, prototyping and low-volume production under one roof, we help customers move faster, reduce costs and maintain control over quality.

Conclusion

Additive manufacturing offers a powerful, often underutilised advantage: the ability to design and produce test rigs, jigs and fixtures quickly, affordably and with total design freedom.

Whether you’re building a functional test rig, a custom assembly jig, or a fixture to improve repeatability, AM gives you a smarter, faster way to get there. And with an experienced design-for-manufacture team behind you, the results are even stronger.

AME-3D is here to support your tooling needs — from concept and CAD to finished, production-ready fixture. Get in touch with our experts today.