With 2022 now in the rear-view mirror, we look forward to 2023 and what it will bring to the industrial 3D printing sector. We continue to see growth in additive manufacturing, with more businesses moving away from traditional manufacturing methods, and we know this will continue to be the case throughout 2023.

Looking to the year ahead, we have collated 3 different topics that we believe will be the trend of 3D printing in 2023, and 3 industries we predict will rely more on this manufacturing method to produce their parts.

Predicted Industries For 3D Printing Growth in 2023:

- Automotive

- Medical

- Film/TV Prop

2023 Additive Manufacturing Trends:

- Sustainability

- On-Demand 3D Printing Services

- Supply Chain Solution

Predicted Industries for 3D Printing Growth in 2023

Automotive

We predict that in 2023, 3D printing within the automotive industry will continue to grow due to the popularity and success that manufacturers have had using 3D printing end-use parts and prototypes.

Rapid prototyping has allowed automotive businesses to quickly get a prototype of an assembly, interior part or external piece of a vehicle printed so they are able to test, validate and present their concepts quicker, pushing them further through the market and one step closer to full-scale production. This has bypassed the traditional methods, with faster turnaround times, better quality and lower costs. As more vehicle manufacturers are producing their next models for the future in 2023, there will be a level of validation, testing and presenting needed to pass the parts & therefore more variants of prototypes will be needed.

Not only has the automotive industry leveraged 3D printing for rapid prototyping concepts, but it is becoming increasingly popular that additive manufacturing methods are being used to create end-use parts. This is because with more materials, each holding different properties, becoming available, they are also becoming more suitable to be used at end-use production.

The UK’s promise to stop the sale of diesel and petrol vehicles in 2030 means electric vehicles will continue to be produced at a higher rate throughout 2023. This is excellent news for our industry because 3D printed parts are the solution to an efficient electric vehicle due to their properties of being lightweight & robust.

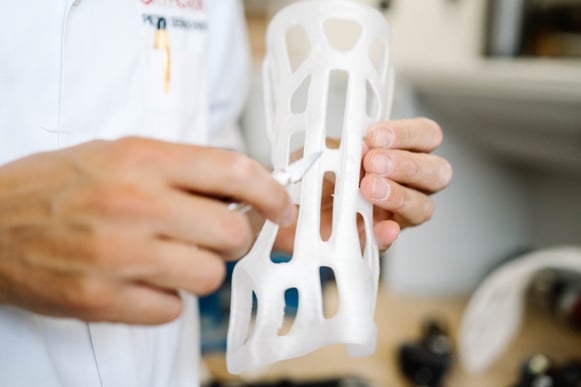

Medical

The first presence of 3D printing being utilized for the NHS in the UK occurred back in 2016, when a 3D model of a patient’s cancerous prostate was created so that medical professionals could accurately target treatment to the area. Ever since then, 3D printing has continued to be a valuable medical asset to the NHS and all of the healthcare industry.

Through 3D technology, replicas of patients’ organs & body parts can be produced, prosthetics, medical device parts & more. As we live in an ageing population, the demand for more medical equipment and advancements grows. We predict that this demand for 3D printing will only increase throughout 2023.

Film/TV Prop

The ability to 3D print what you want, when you want grants prop and model makers in the film and TV industry the freedom to explore their creativity. The customisation and repeatability that 3D printing offers is why film and TV prop makers always opt for this way of manufacturing. There can be no errors when a movie or TV program is released, and with the accuracy of additive manufacturing, there is little chance that this will happen.

The film & TV industry is always growing, with more demand for high-quality realistic props, prosthetic make-up parts and models. We predict more production studios will adopt more 3D printing methods for their props throughout 2023.

2023 Additive Manufacturing Trends

Sustainability

As we move into an ever-changing world, the damage done through harmful manufacturing methods and a range of other factors continues to be a huge issue. With a large portion of efforts from businesses being dedicated to making their processes and products more sustainable, consumers are now picking up on this and it has become a USP for many companies.

3D Printing is more sustainable in comparison to traditional manufacturing methods. This is because it builds up parts from layers, meaning less waste is created. Parts are up to 50% lighter than traditionally manufactured parts, meaning less energy. Leftover SLS nylon powder can be re-used and repurposed rather than waste. There are many ways in which 3D printing is already pushing sustainability efforts in comparison to other manufacturing methods.

Materials such as PLA plastics are better for the environment and biodegradable in comparison to ABS. More businesses will shift to further sustainable materials where possible in 2023 and begin to review how they can make their processes environmentally friendly. There is a big scope as to how additive manufacturers can take these steps and implement them, no doubt this will be a major trend for the upcoming year.

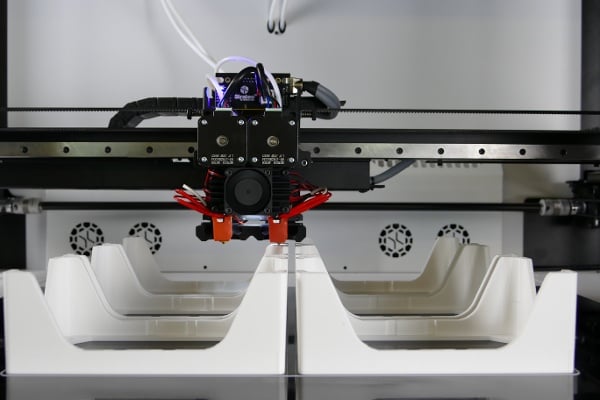

On-Demand Faster 3D Printing Services

On-demand 3D printing services will grow in 2023 because more companies will require quicker turnaround for already designed parts that are ready for manufacture. This is a very competitive point when quoting and onboarding new customers, they want the best price, but the quickest times and additive manufacturing companies need to cater to their needs otherwise they will be looking elsewhere.

Instant quotes & being able to order directly online saves customers valuable time and makes their purchasing process easier when it comes to getting their 3D printed parts. Enabling customers who have repeat orders to instantly re-order streamlines the manufacturing process.

This will be a bigger demanding point for the 3D printing industry in 2023, more efficient processes that allow a seamless customer journey.

Supply Chain Problem Solver

Supply chain issues are common for businesses and as the economy changes along with the way we manufacture, this can leave vulnerabilities for businesses’ supply chains in 2023, leaving them struggling and having to look at alternatives. This will give additive manufacturing the opportunity to become a popular option to solve supply chain issues due to the flexibility and array of options that it brings to the table.

When supply chain disruptions come, additive manufacturing companies can offer quick turnaround times, cost-effective prices and a solution to the production issues that companies have. There will be more dependency on 3D printing businesses in 2023 to help solve these pain points within supply chains.

Summary

There you have it, these are our predictions for the year ahead. Additive manufacturing continues to rise. If you’re interested in learning how our 3D printing, rapid prototyping & low volume production services can benefit your business, get in touch and our sales team will be happy to discuss this with you.

T: +44 (0)1909 550 999

Got your CAD file ready? No problem, submit it here for a fast quote.